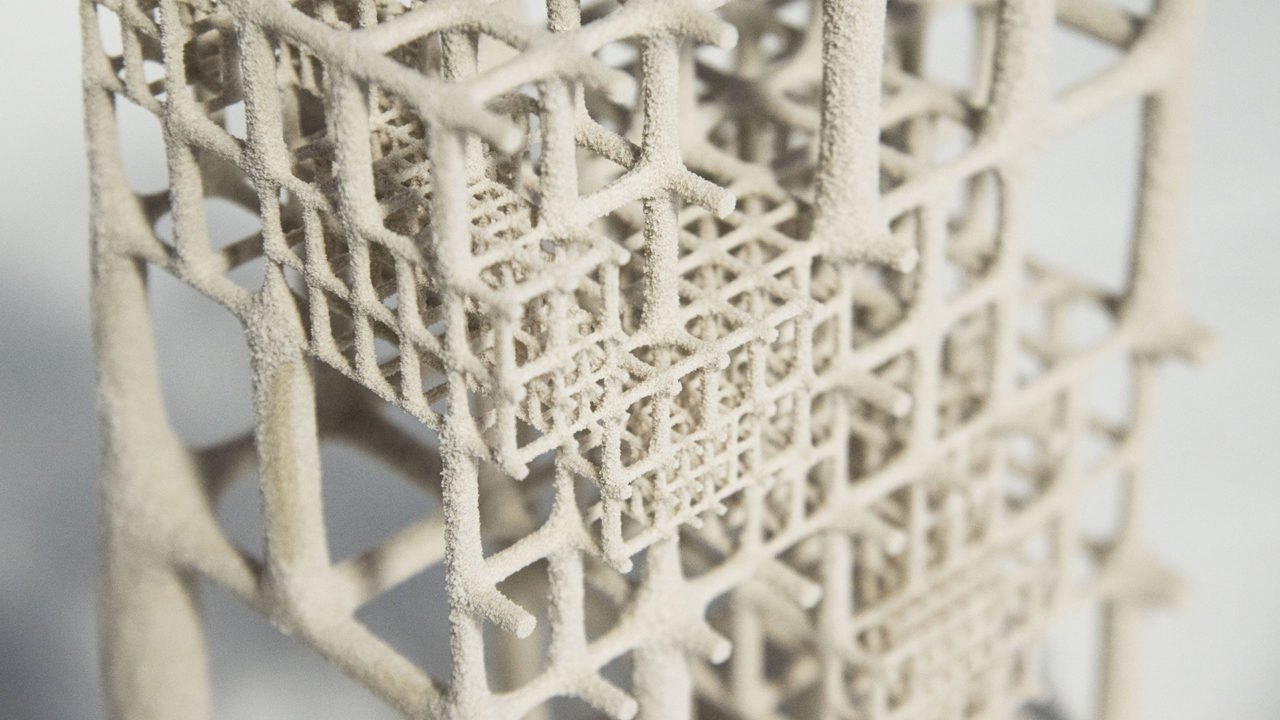

SmartBrick is the name of a one-week module I ran in the past three years in T1 of the masters of advanced studies program in architecture and digital fabrication (MASdfab), to introduce the students to the concepts of volumetric modeling and binderjet 3D printing. The assignment is to select one specific building component, a part of a larger assembly, and augment its functionality. This enhancement should reflect the full potential of binderjet 3D printing as a mode of manufacturing. The geometric freedom offered by it allows us to integrate additional functions, detail the brick throughout the entire volume, and not just at its surface and control the material at the level of a single grain of sand.

The students’ designs are very heterogeneous, and many different functional aspects and features have been studied and integrated. One group dynamically controls the gradient of porosity to smoothly control the view in a less binary manner than punching holes into a wall. Another group carves out intricate sequences of internal chambers for improved acoustic absorption. An unexpected balancing behavior is achieved by one group through non-homogenous internal density distribution. One team blurs the conventional boundaries between structure and ornament by seamlessly adjusting strut diameters according to functional needs. And yet other groups investigate the spatial nesting of non-repetitive tiles for print space optimization, self-alignment, and positioning interfaces, or passive cooling through highly evaporative lattice structures.

DBT project page: dbt.arch.ethz.ch/course/smartbrick